In the world of industrial processing, precision, durability and efficiency are critical. Whether in pharmaceuticals, food production, or chemical manufacturing, mixing tanks play a vital role in ensuring consistency, safety, and quality.

Brisbane Tank Manufacturing has positioned itself as a leader in this space offering innovative stainless steel mixing tanks that exemplify ingenuity and efficiency.

Why Stainless Steel?

Stainless steel is the material of choice for industrial mixing tanks due to its exceptional durability, resistance to corrosion and ease of maintenance. Unlike other materials, stainless steel withstands extreme temperatures, aggressive chemicals and high pressure conditions, making it ideal for industries where hygiene and longevity are paramount.

At Brisbane Tank Manufacturing only the highest grade stainless steel, such as 316 is used to ensure reliability in even the most demanding applications. This results in tanks that not only endure but also enhance efficiency in production processes.

Innovative Design and Engineering

Brisbane Tank Manufacturing integrates cutting edge design and engineering techniques into every mixing tank. Some key innovations include:

Custom Agitation Systems: The company designs specialised mixing mechanisms tailored to the viscosity and chemical properties of each substance. Whether it’s high speed impellers or gentle blending paddles, these systems optimise mixing efficiency.

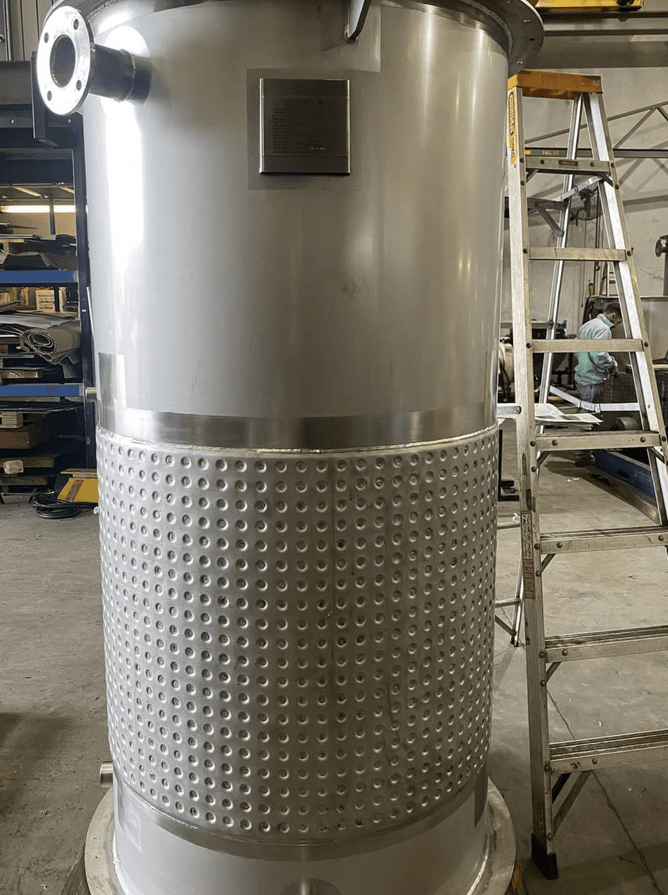

Precision Temperature Control: Integrated heating and cooling jackets ensure that products are maintained at optimal processing temperatures, reducing waste and enhancing consistency.

Automated Mixing Solutions: With automation and advanced control systems, Brisbane Tank Manufacturing's tanks streamline production reduce manual labour and improve safety.

Sanitary and Hygienic Construction: For industries like pharmaceuticals and food production, smooth, crevice free designs prevent contamination and ensure compliance with stringent regulatory standards.

Maximising Efficiency in Industrial Applications

Efficiency is key to profitability, and Brisbane Tank Manufacturing’s stainless steel mixing tanks are designed to minimise downtime and optimise energy use. Features like quick access ports, easy to clean interiors and advanced mixing technology contribute to faster batch processing and reduced operational costs.

Additionally, the company’s commitment to sustainability means that its tanks are built with energy efficiency in mind. Reduced heat loss, optimised motor functions and durable construction all contribute to a lower environmental footprint while maximising output.

Choosing Brisbane Tank Manufacturing means investing in reliability, performance, and innovation. The company’s expertise in stainless steel fabrication combined with a deep understanding of industry needs ensures that every tank is built to meet specific client requirements.

With a reputation for quality craftsmanship and cutting edge engineering, Brisbane Tank Manufacturing continues to set the standard for industrial mixing solutions. If you need a partner you can 100% rely on then contact us and let’s talk tanks.