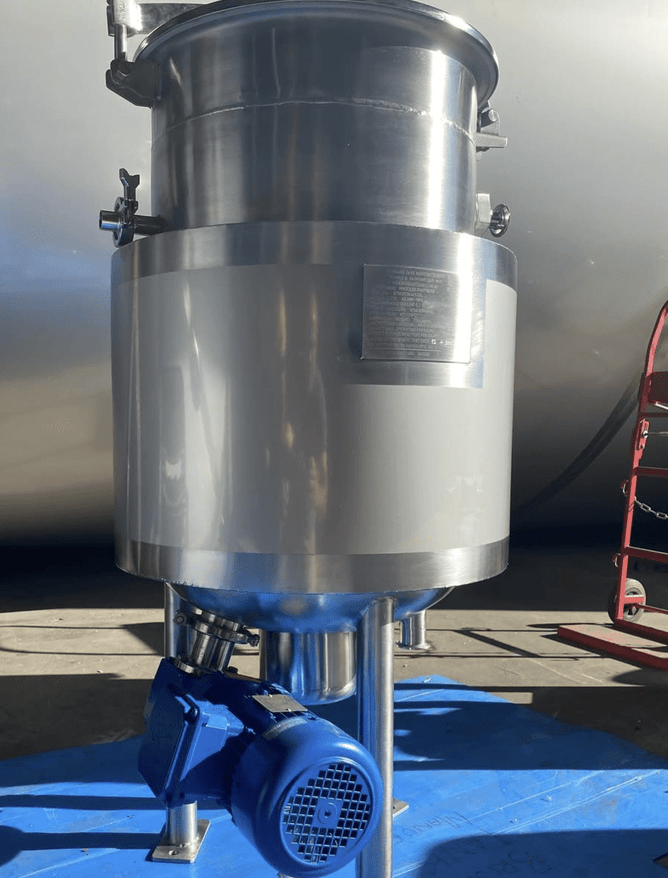

Stainless steel tanks are a fundamental component in a wide range of industries, providing reliable storage, mixing and processing solutions.

At Brisbane Tank Manufacturing we specialise in designing and fabricating high quality stainless steel tanks that meet the diverse needs of our clients.

But what exactly do these tanks do, and why are they so essential?

Storage Solutions for Liquids and Solids

One of the primary functions of stainless steel tanks is the safe storage of various substances including liquids, gases and dry bulk materials. Industries such as pharmaceuticals, food and beverage, chemicals and water treatment rely on these tanks for their ability to maintain product integrity and prevent contamination.

Food & Beverage Industry: Stainless steel tanks store ingredients like dairy, juices and alcoholic beverages, ensuring they remain safe and uncontaminated.

Chemical Industry: These tanks hold and process corrosive chemicals, thanks to their superior resistance to rust and chemical reactions.

Pharmaceutical Industry: Used to store and mix sensitive materials in sterile environments preventing bacterial growth and contamination.

Mixing and Blending for Industrial Processes

Stainless steel tanks are also widely used in mixing and blending applications helping industries produce uniform products. Brisbane Tank Manufacturing designs tanks with customised agitation systems, ensuring even distribution of ingredients and optimal consistency.

Pharmaceuticals: Used in the preparation of liquid medicines and syrups where precision mixing is crucial.

Food Production: Essential for mixing sauces, dairy products and other consumables while maintaining hygiene standards.

Chemical Processing: Enables uniform mixing of reactive substances while ensuring safety.

Temperature Control for Processing Efficiency

Many industrial processes require precise temperature management and stainless steel tanks with integrated heating or cooling systems facilitate this.

Breweries & Wineries: Temperature controlled tanks help in fermentation and aging processes.

Cosmetic Industry: Used to maintain the stability of ingredients during product formulation.

Industrial Manufacturing: Ensures chemicals and raw materials remain at optimal temperatures for processing.

Filtration and Purification Applications

Stainless steel tanks play a vital role in water treatment and effluent management. Filtration tanks designed by Brisbane Tank Manufacturing help remove impurities, making them crucial for environmental sustainability and compliance with industry regulations.

Wastewater Treatment: Used for sedimentation, filtration, and chemical treatments.

Pharmaceuticals & Food Industry: Ensures purified water is available for safe production processes.

Chemical Processing: Helps remove contaminants before materials are further processed.

Why Choose Brisbane Tank Manufacturing?

Brisbane Tank Manufacturing combines innovation, engineering expertise and premium stainless steel materials to deliver tanks that exceed industry standards. Whether for storage, mixing, temperature control, or purification our stainless steel tanks provide durability, efficiency, and superior performance.

If you're looking for high quality stainless steel tanks tailored to your industry’s needs, Brisbane Tank Manufacturing is your trusted partner. Contact us today to learn how we can support your operations with our advanced tank solutions and let’s talk tanks!