Every step taken to ensure quality carries immense significance.

At BTM, we understand the critical importance of delivering products that not only meet but exceed the highest standards of excellence.

As part of our commitment to quality assurance, every tank that leaves our workshop undergoes rigorous testing for leaks, with dye penetrant testing serving as a crucial component of our process.

What is dye penetrant testing?

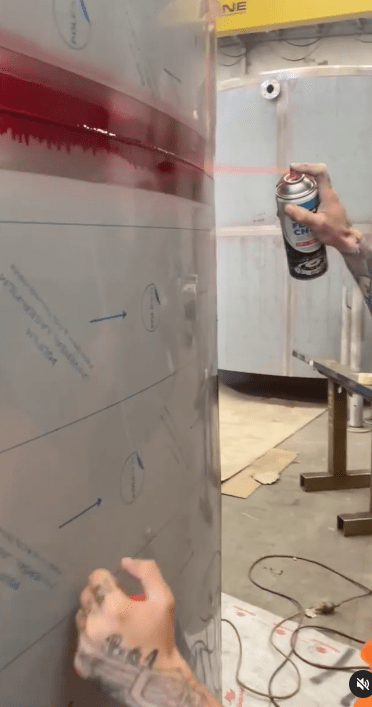

Dye penetrant testing, also known as liquid penetrant testing or PT testing, is a non-destructive application method used to detect surface-breaking defects in materials.

It’s just another step we take to safeguard against any potential flaws before we despatch to its site so we this final 10% of the tank manufacturing process is just as important as the first design phase.

Precision in Inspection

Dye penetrant testing offers a level of precision that is indispensable in identifying even the smallest imperfections in the surface of a tank.

By applying a highly visible dye to the surface and allowing it to seep into any surface defects, our inspectors can carefully examine the entire tank for signs of any leaks. We make sure there are no potential issues that go unnoticed.

Comprehensive Quality Assurance

At BTM, we leave no stone unturned when it comes to quality assurance.

Dye penetrant testing serves as another layer of protection, complementing our comprehensive approach to ensuring the reliability and safety of our products. By subjecting every tank to this rigorous examination, you can rely on our tanks to do exactly what’s needed when they are installed on site.

Continuous Improvement

Innovation and improvement are at the core of our ethos at BTM. By integrating dye penetrant testing into our quality assurance system, we continually refine our processes and raise the bar for excellence. Every member of our team understands this and we’re proud of the fact they all our crew take this as a given.

Each test serves as an opportunity to learn and adapt, as we continuously seek to improve and advance in our craft.

Peace of Mind for Our Clients

For our clients, investing in a Brisbane Tank Manufacturing tank isn't just a transaction; it's a decision to prioritise quality, reliability, and safety. Dye penetrant testing provides them with the assurance that they're receiving a product that has undergone rigorous scrutiny and emerged unblemished. It's a testament to our dedication to their success and our unwavering commitment to delivering value that extends far beyond the workshop floor. Ready to talk tanks? Let’s chat