As you quite rightly would know steel is the most commonly used material for industrial storage tanks and this is because of its strength and durability.

You have to be pretty tough to stand up to the weather conditions here in Australia; we have extreme heat, we can have high winds, and we can have down pours that come out of nowhere so you can rest assured when it comes to the tough jobs; our design and manufacturing experts note specific requirements and contents being stored so we choose what steel is best for the job.

Here’s are a couple of the most common steel options for the manufacturing of industrial storage tanks and some interesting steel fun facts too:

Carbon Steel:

Carbon steel is one of the most widely used materials for industrial storage tanks. It is known for its strength and cost-effectiveness. However, it may require internal coatings or linings to prevent corrosion when storing certain liquids or chemicals.

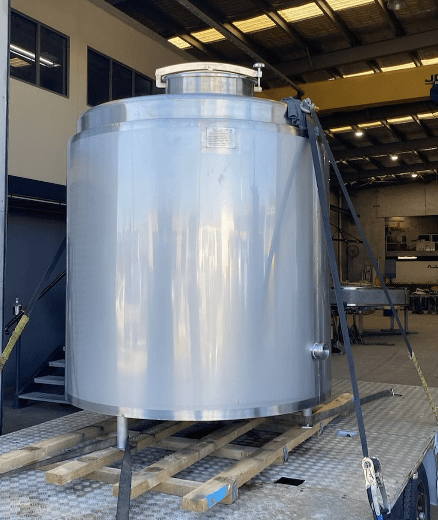

Stainless Steel:

Stainless steel is an excellent choice for tanks that need to resist corrosion, particularly when storing corrosive chemicals or food products. It is available in various grades, with 304 and 316 being the most common choices due to their corrosion resistance properties.

Stainless steel is one of those “jack of all trades” type steels because it is also commonly used as structural supports for buildings and did you know in 1984, engineers used stainless steel as structural support for the Statue of Liberty in New York? Now it’s used all over the place for its structural integrity. If it’s good enough for the Statue of Liberty it’s good enough for BTM!

Some more fun facts about steel which makes us feel proud of this material are ….

Steel is one of the most recycled materials in the world. According to the American Iron and Steel Institute they have estimated that 88% of steel in the world is recycled. That’s pretty cool isn’t it. So not only good for building and storing stuff; it’s good for our environment.

Steel doesn’t loose any of its strength when it's recycled and it can be made even stronger with galvanised steel strapping which also helps to prevent rust so a win win all round.

And to cap it all off; steel is the main component towards making wind turbines and solar panels so here’s to steel and its incredible and diverse uses and strength.

We at Brisbane Tank Manufacturing give steel a big green tick of approval!

So just to finish off the choice of steel for an industrial storage tank will depend on factors such as the type of contents being stored, environmental conditions, and required maintenance.

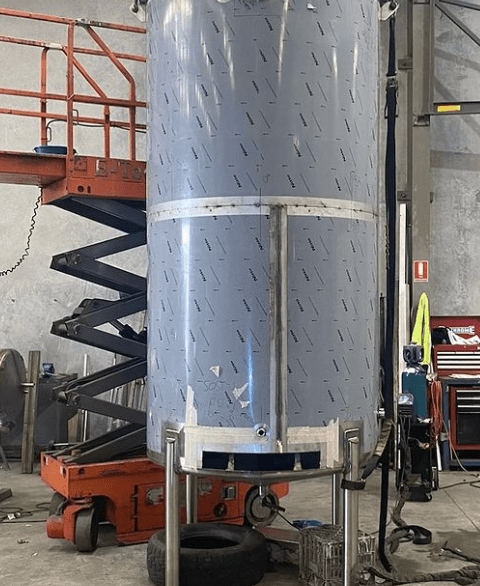

We make sure it's a key part of any tank manufacturing project to select the right steel option to ensure the longevity, safety, and performance of the storage tank in your specific application.

Additionally, proper maintenance and protective coatings or linings can be used to extend the life and performance of steel storage tanks. When you need a top tank, contact us today because we love nothing better than talking tanks with you!